What are hazardous goods?

Hazardous goods refer to things (e.g. solutions, materials, mixtures or objects) to be transported on public routes, that can pose a danger to public safety and order, to assets, or to the life and health of humans or animals due to their natural properties or chemical or physical state. Hazardous goods transport is subject to national and international laws and regulations.

Classes of hazardous goods.

GGV classification of hazardous goods according to the UN.

Because hazardous goods are transported not only within a country but also internationally, this hazardous goods classification is applicable worldwide.

| Classification | Description | Required hazardous goods packaging |

| Class 1 | Explosive substances and objects containing explosive substances (with 7 subclasses) | Hazardous goods packaging for explosive substances |

Class 2.1 | Flammable gases | Hazardous goods packaging for flammable gases |

Class 2.2 | Non-flammable gases | Hazardous goods packaging for non-flammable gases |

| Class 2.3 | Toxic gases | Hazardous goods packaging for toxic gases |

| Class 3 | Flammable liquids | Hazardous goods packaging for flammable liquids |

| Class 4.1 | Flammable solids | Hazardous goods packaging for flammable solids |

| Class 4.2 | Spontaneously combustible substances | Hazardous goods packaging for spontaneously combustible substances |

| Class 4.3 | Substances that form flammable gases on contact with water | Hazardous goods packaging for substances that form flammable gases on contact with water |

| Class 5.1 | Oxidising substances | Hazardous goods packaging for oxidising substances |

| Class 5.2 | Organic peroxides | Hazardous goods packaging |

| Class 6.1 | Toxic substances | Hazardous goods packaging for toxic substances |

Class 6.2 | Infectious substances | Hazardous goods packaging for infectious substances |

| Class 7 | Radioactive | Hazardous goods packaging for radioactive substances |

| Class 8 | Corrosive | Hazardous goods packaging for corrosive substances |

| Class 9 | Miscellaneous hazardous substances and objects | Hazardous goods packaging for miscellaneous hazardous substances and objects |

Advantages of hazardous goods packaging made of aluminium.

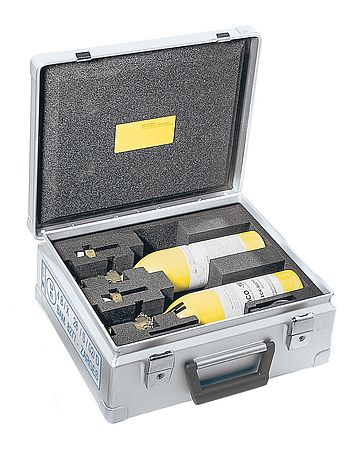

Hazardous goods containers made of aluminium – ZARGES hazardous goods packaging

Using aluminium in hazardous goods packaging has many benefits over using other materials. It is highly sturdy and resistant while having low weight, is very durable and can therefore be reused over and over again, can be closed securely, and offers optimal protection even under extreme conditions.

IMPORTANT!

Hazardous goods packaging made of plastic is not allowed to be used for more than 5 years or be older than 5 years. After this period, hazardous goods containers made of plastic are no longer considered secure packaging (tip: this also applies to spare jerry cans in cars).

Why choose hazardous goods packaging made by ZARGES?

Choose between safe and safer.

ZARGES offers you a wide range of sizes and models. Our own test centre, which is recognised and monitored by BAM (German Federal Institute for Materials Research), carries out type testing in order to obtain approvals such as UN 4B, UN 4BV and UN 50B in a quick and uncomplicated manner.

A large selection of accessories and interior fittings ensure that your hazardous goods will remain well protected during transport.

FAQ: Frequently asked questions about hazardous goods

Here we will be answering frequently asked questions on the topic of hazardous goods. If you have any questions that are not answered here, please contact our hazardous goods packaging specialists!

What hazardous goods are allowed be transported in ZARGES cases?

Hazardous goods transport is regulated by various laws, depending on the mode of transport. The ADR regulates transport by road, and the RID transport by rail. Transport by air is regulated by the IATA DGR. Most dangerous goods are listed in these regulations. The approved dangerous goods containers are also listed alongside the dangerous goods they are allowed to carry. Using the UN number, you can select the packaging that is approved for the substance in question.

What is ADR?

ADR is the abbreviation for the European Agreement concerning the International Carriage of Dangerous Goods by Road, or in French: Accord Européen relatif au transport international des marchandises dangereuses par route.

What is the purpose of the approval for transport of dangerous goods?

Every hazardous goods packaging requires a type approval which certifies that the containers have been tested for leak-tightness and comply with further specific requirements.

In Germany, new approvals are granted exclusively by the Federal Institute for Materials Research and Testing (BAM).

How should hazardous goods or hazardous goods packaging be labelled?

Hazardous goods have to be clearly labelled during transport and shipping. The process of doing so is known as labelling. The label has to provide information on the composition of the goods being transported as well as the possible hazards associated with it.

Hazard labels have a diamond shape. They must be affixed to the packages and shipping containers and must contain information on the types of hazard associated with the substances being transported.

More information on hazard warning labels can be found e.g. at German Federal Ministry of Transport, Building and Urban Development (BMVBS).

Hazardous goods packaging by ZARGES can be equipped with all necessary hazardous goods labels and hazard labels.

What is a type approval (and a UN number)?

A type approval is a permit for the series production and labelling of an item of packaging used for transporting hazardous goods.

What does the number behind the X on the UN approval label mean?

This is the maximum allowable gross weight (outer packaging incl. inner packaging and dangerous goods).

What is the UN number for labelling hazardous substances?

The UN number (see list of UN numbers on Wikipedia) is a four-digit number assigned by the United Nations Committee of Experts on the Transport of Dangerous Goods. The UN number is also called the substance number.

Besides the UN number and the naming and description of a hazardous substance, the Hazardous Goods Database also provides information on what packaging may be used for the transport of the substance in question.

Besides hazard labels, packages containing dangerous goods also have to be labelled with the corresponding UN number.

ZARGES manufactures hazardous goods packaging and hazardous goods containers. Our products have been tested and given the approval (including a UN approval number).

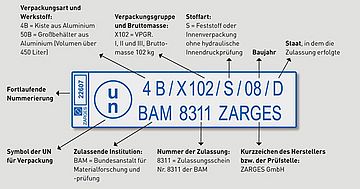

How is the UN approval number structured?

- Packaging type and material of the hazardous goods packaging

- Packing groups X, Y or Z

- Gross weight that the packaging and content must not exceed

- Material type

- Year of manufacture

- Country in which approval was granted

- Approving institution

- Approval number

- Abbreviation of manufacturer or testing centre

How do I find the right permissible packaging?

What container you are allowed to use depends on the goods to be transported.

Do ZARGES dangerous goods products have to undergo regular reinspections?

No, because aluminium is not subject to any ageing processes unlike, for example, plastic. A visual inspection of the aluminium cases for external damage is sufficient.

What is the maximum permissible gross weight for the K 470 series of containers?

The maximum permissible gross weights of hazardous goods cases are shown on the respective hazardous goods label. For the K 470 series, this ranges from 26 kg to 200 kg. For special containers the maximum gross weights can be even higher.

Can I transport my hazardous goods directly in ZARGES cases?

No, the cases are approved for use as composite packaging. An insert is always required.

How are hazardous goods and hazardous goods packaging categorised?

Packaging groups: Hazardous goods are categorised into three packing groups (I, II and III for high, moderate and low hazard, respectively) that correspond to the performance letters X, Y and Z of hazardous goods packaging. Accordingly, hazardous goods packaging with a particular performance letter may only be used for hazardous goods of certain categories.

Types of packaging: The common types of packaging for hazardous goods are drums or barrels, canisters, cases or boxes, bags, combination packaging and pressure vessels made of a wide range of materials such as steel, aluminium and other metals as well as wood, cardboard, plastic, fabrics, etc.

Where can I obtain approval certificates for ZARGES hazardous goods packaging?

We will be happy to provide you with the approval certificates for our most common hazardous goods packaging by request. The certificates are also available on the website of the German Federal Institute for Materials Research and Testing (BAM).

When is it necessary to have a hazardous substances officer?

Companies that transport hazardous goods on a daily basis have a hard time dealing with the many different laws and regulations. In the worst case, they may even (unwittingly) become criminally liable. If in doubt, consult a hazardous substances officer or an external hazardous substances consultant. They will be able to advise you on individual cases or draw up an overall concept for you.