E-Mobility, E-Bikes, Power-Tools, Photovoltaic Energy Storage, Automotive Industry – the use of lithium-ion batteries is becoming increasingly common. The transport and storage of lithium batteries, defective or intact, is subject to strict safety regulations. In conjunction with a world market leader for e-bike batteries, ZARGES has developed a safety container for the storage and transportation of damaged or defective batteries. In cooperation with the world's leading manufacturers of rechargeable batteries for power tools and in the automotive industry, ZARGES has developed a perfectly optimised safety container for the storage and transport of lithium-ion batteries - even if they are defective or damaged.

The advantages of storing and transporting batteries and rechargeable batteries in the ZARGES Akku Safe are obvious, because uncontrolled energy release in rechargeable batteries and accumulators is fire hazard and causes great damage.

There is a lot to consider when transporting dangerous goods in accordance with ADR, especially in the case of critically defective batteries. ZARGES Akku Safes make the dangerous goods logistics of batteries and cells a little easier and the recycling (reverse logistics) of lithium batteries safer.

LiPo Safe, Akku Safe or Lipo Box – many names, one goal: maximum safety when handling rechargeable batteries and batteries.

| Number of handles | 3 |

|---|---|

| Outer dimensions LxBxH (mm) | 600×600×250 |

| Warranty | 10 Years |

| max. gross mass hazardous goods approval | 65 kg |

| Weight | 11.5 kg |

| Interior use | 3 compartments for e-bike batteries |

| Concept | Cover foil and Cirrux cushion |

| Approval for critically defective Li-ion batteries | Up to 814 Wh |

| Number of handles | 3 |

|---|---|

| Outer dimensions LxBxH (mm) | 600×400×250 |

| Warranty | 10 Years |

| max. gross mass hazardous goods approval | 65 kg |

| Weight | 11.5 kg |

| Interior use | Flexibel |

| Concept | Additionally with silica plates and metal lining (puncture-proof, for higher nominal energies) |

| Approval for critically defective Li-ion batteries | Up to 1.384 Wh |

Transporting lithium batteries really safely with the ZARGES Akku Safe & Akku Safe Universal

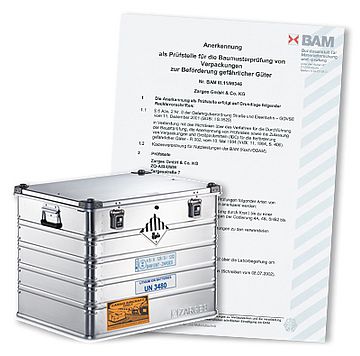

- Hazardous goods packaging certified for lithium-ion batteries UN 3480, UN 3481.

- Suitable for transporting prototypes, damaged or defective batteries, critically defective batteries and batteries for disposal and recycling.

- Also passed fire tests involving critically defective batteries with nominal capacity of over 1,000 Wh (request specification from ZARGES).

- Maximum outside temperature below 100°C, no flames or splinters escaping in the event of an accident.

- High dielectric strength, i.e. also suitable for high-performance batteries, such as those used in power tools.

- Padding and absorbent material are non-flammable, non-conductive and dust-free.

- The box is also perfect for the storage of lithium-ion batteries.

- Made in Germany

- Approved hazardous goods packaging cannot be taken back.

Transporting and shipping lithium ion batteries

Since lithium ion batteries react with many substances and tend to overheat (fire hazard!), some points must be observed for shipping and transport. The advantages of lithium batteries & rechargeable batteries cannot be denied: High energy density with low weight, insensitivity to the memory effect and low self-discharge make this type of energy storage the first choice, not only for mobile devices. On the other hand, extremely high charging and discharging currents can occur in the event of a defect or short circuit. This can result in uncontrollable heat development, even fire or explosion. The ZARGES Akku Safe is designed in such a way that even in the case of burning lithium batteries, the development of heat and smoke is reduced to a minimum.

The ZVEI - Zentralverband Elektrotechnik und Elektronikindustrie e. V (German Electrical and Electronic Manufacturers' Association), together with the EPTA - European Power Tool Association, has developed leaflets summarising important guidelines, packaging instructions and labelling

5 tips for the safe handling of lithium-ion batteries during transport and storage

Lithium ion batteries are small storage devices for a lot of energy. It is precisely this advantage that makes them so dangerous, because defective and carelessly stored batteries have a real potential for danger: toxic fumes, explosions or dangerous fires. For safer handling, it is essential to follow these 5 tips.

1. Charge lithium-ion batteries correctly

The batteries may only be connected and charged on chargers that are approved for this purpose (ideally by the manufacturer). Do not charge the batteries without supervision. In addition, ensure that the ambient temperature is suitable: Not too hot and not too cold - "room temperature", where we also feel comfortable, is well suited. If lithium-ion batteries have been used in a very cold or warm environment, they should first be brought to room temperature before charging.

2. Store lithium-ion batteries correctly. Do not store too hot or too cold.

If several batteries are stored together (collective container) and short circuits cannot be ruled out, the battery terminals must be secured with adhesive tape. Lithium-ion batteries must not be exposed to direct sunlight or other strong heat sources for long periods of time. Flammable or combustible objects must be kept at a safe distance of at least 2.5 metres. The batteries are best stored in a separate room or in a suitable, non-flammable container.

3. How to deal with defective lithium-ion batteries. What to do?

If lithium batteries are broken and have reached the end of their life, they must be collected at separate storage locations without fire loads. TRGS 510, which regulates the storage of hazardous substances in portable containers, must be taken into account. The damaged or defective batteries must then be taken immediately to a collection point. ATTENTION: Broken and no longer functioning lithium-ion batteries may only be transported in approved containers with pressure relief and are subject to dangerous goods legislation. This contains regulations that specifically govern the transport of defective lithium-ion batteries.

4. Fire protection measures at workplaces when using lithium-ion batteries

If work is carried out at the workplace with or in the vicinity of large quantities of lithium-ion batteries, this workplace must be classified as a work area with an increased fire hazard according to ASR A2.2. Depending on the risk assessment, various additional fire protection measures must be taken (e.g. fire extinguishing systems or fire alarm systems).

5. What to do in an emergency? Fire or smoke development in lithium-ion batteries.

Emergency measures in the event of a fire in a battery must already be defined in advance (also through the risk assessment) and the organisational emergency measures must be documented. To prevent the emergency situation from escalating even further, the exact procedure must be clear to everyone involved: Who calls the fire brigade, who informs the staff, who is to be evacuated and where are the emergency boxes in which the batteries are placed and isolated?

It is advisable to seek advice from experts (experts or the fire brigade) in the event of a battery fire, so that you are well prepared in the event of an emergency. Last but not least, the right choice of extinguishing agent is crucial: Small batteries can still be cooled down by water, but lithium is very reactive and can react violently. The experts recommend which extinguishing granules or extinguishing agents are best suited.

Do you have any questions concerning our hazardous goods packaging?

Outer packaging for hazardous goods (also known as hazardous materials) available in standard sizes and special sizes with approval; also available are complete packaging for hazardous goods (composite packaging) and special solutions for hazardous goods packaging and transport.

Tel.: +49 881 687-131

Fax: +49 881 687-484

E-mail: special.systems@zarges.de

Over 30 years of experience in packaging for dangerous goods

Rely on more than 30 years of experience in the field of hazardous goods and the complete reliability of our packaging solutions.

Our in-house testing laboratory – approved by the Federal Institute for Materials Research (BAM, Berlin) – guarantees fast and accurate test procedures.

Are there alternatives to the ZARGES battery safe?

There are certainly alternative lipo boxes, lipo cases or lipo safes in the various price segments. On the one hand, there are fire protection bags and fire protection cases, which are a cheaper alternative, and on the other hand, battery cabinets, for example, which are on average much more expensive than the ZARGES battery safe. Which product is ultimately the best must be decided according to the application. ZARGES guarantees comprehensive fire protection for the ZARGES Akku Safe, which is not comparable with the protective properties of alternative protective containers.